Facilities

- Home

- Facilities

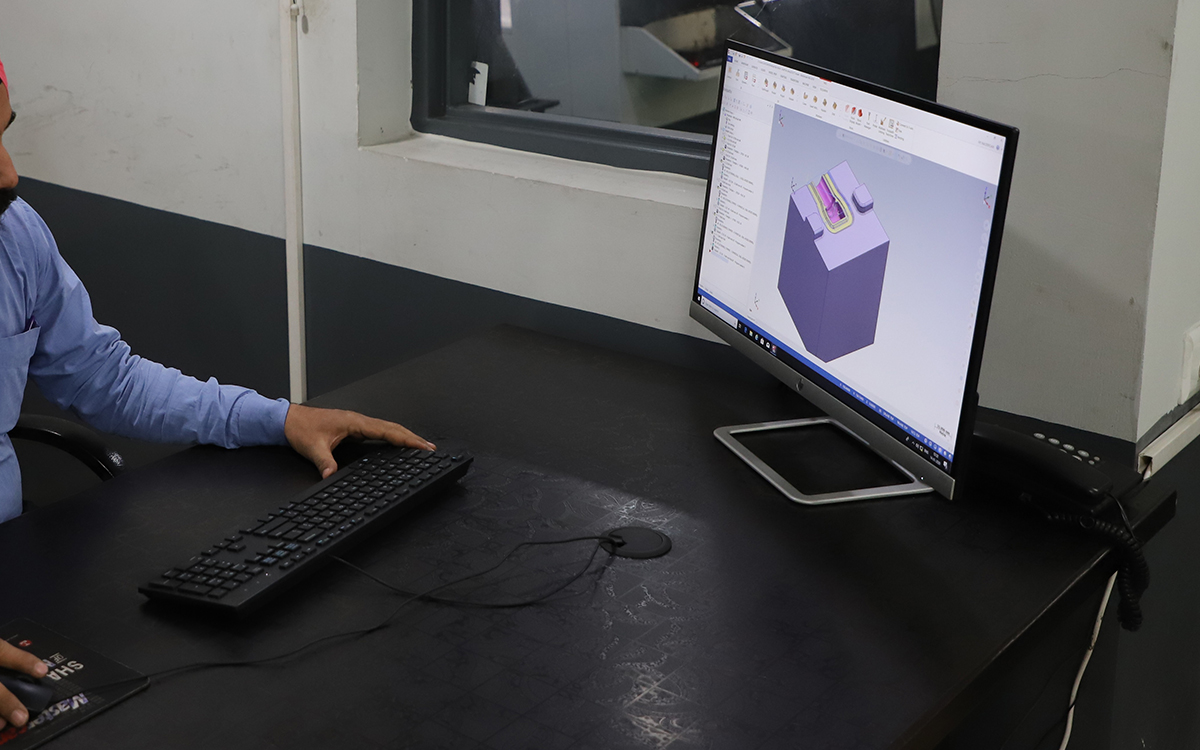

Tool & Die

Our advanced Tool & Die facility enables in-house manufacturing of dies and fixtures. Equipped with ‘Q form’ simulation software for the forging dies, we thoroughly examine die designs ensuring superior grain flow quality.

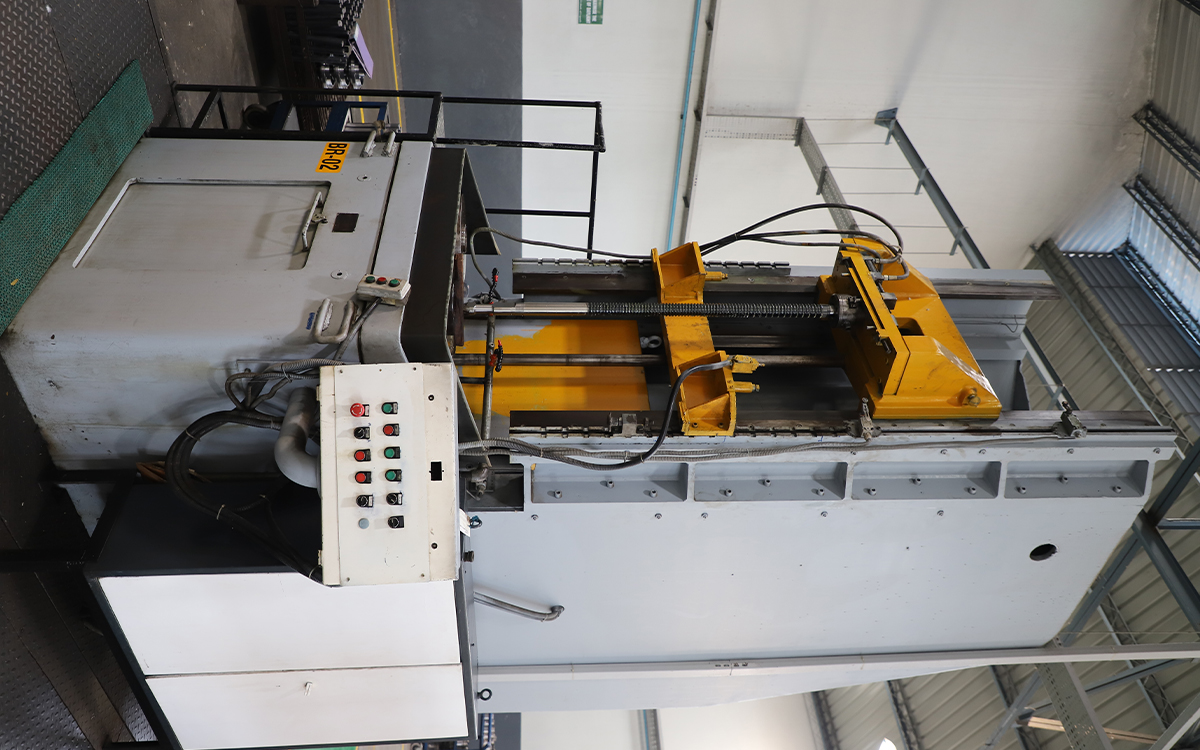

Machining

We have advanced & digitalized machining lines equipped with stringent process controls. Our facilities feature CNC Turning, VMC with 4-axis, Rack rolling, CNC hobbing, Surface Broaching, Internal broaching, and CNC Grinding machines ensuring the highest standards of accuracy and excellence. We conduct statistical controls with structured inspection and testing protocols for all components during machining.

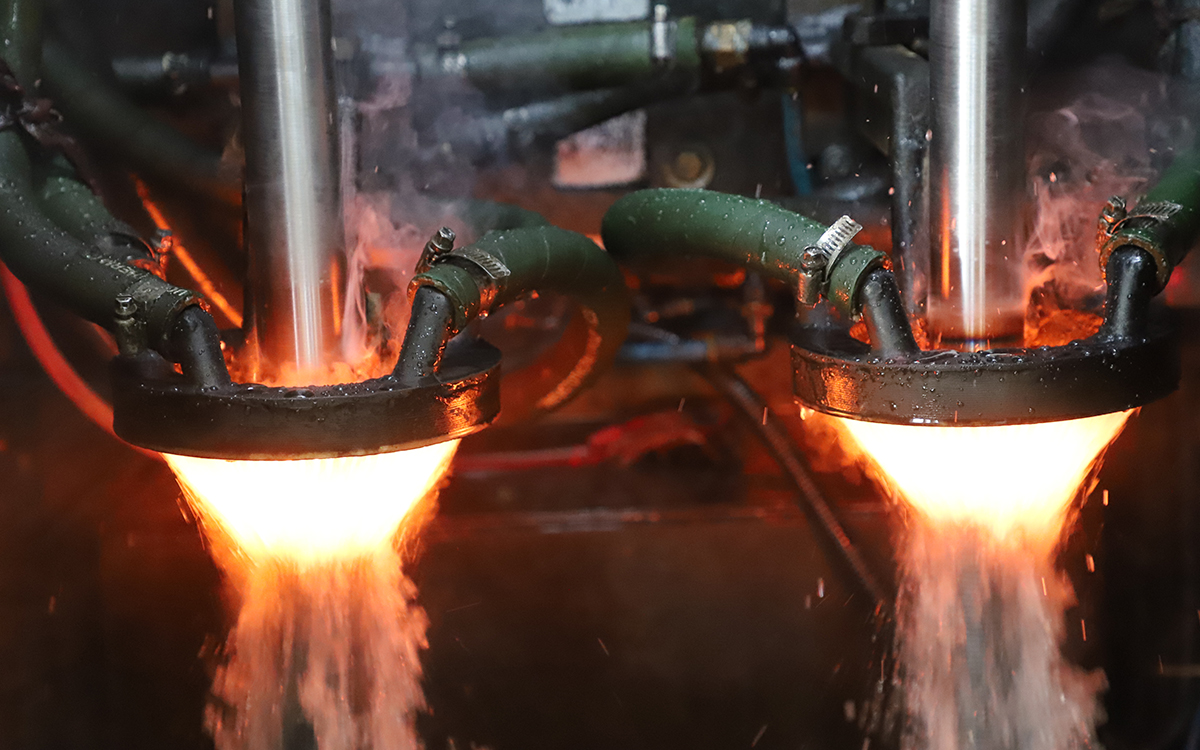

Heat Treatment

Our manufacturing facility specializes in a diverse range of advanced heat treatment processes including normalizing, normalizing elimination and quench & temper heat treatment, all managed with SCADA control and CQI-9 compliant for controls and consistency. We have world class induction hardening machines with poke yokes to ensure highest quality assurance level. Our controlled atmospheric furnace capabilities enable us to maintain precise environmental conditions, enhancing material properties and reducing oxidation. These technologies supports us to deliver quality parts to our esteemed customers.

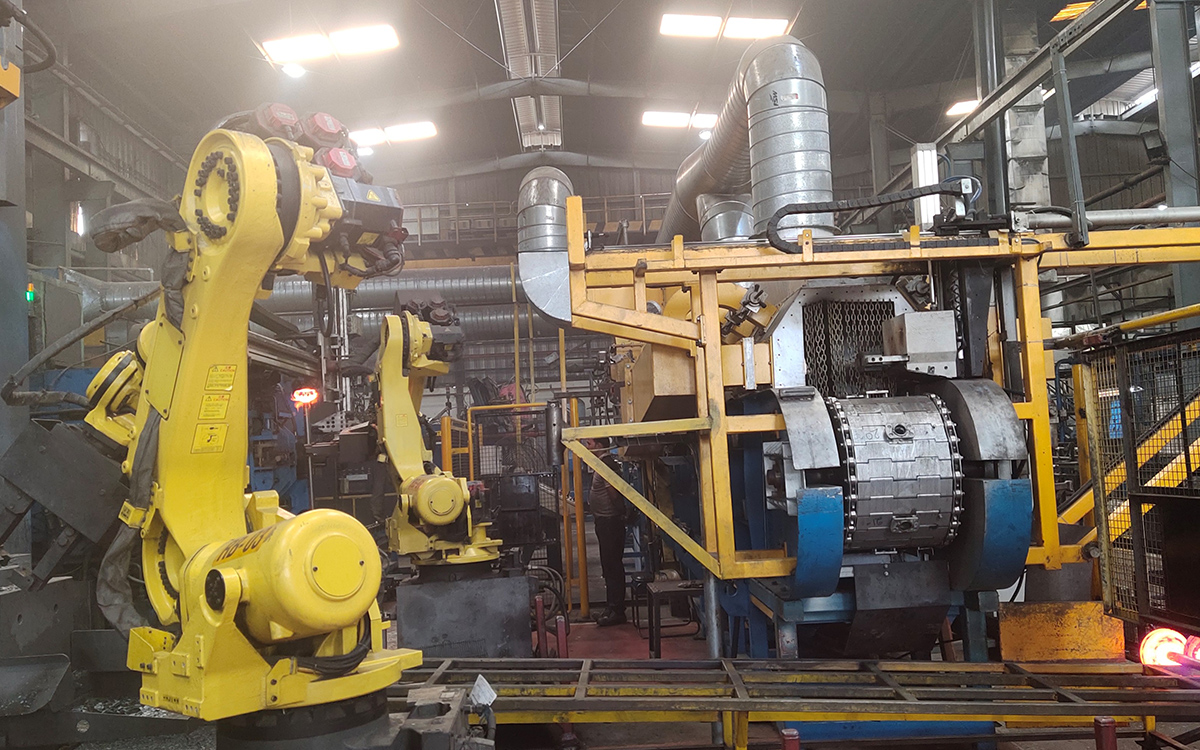

Forging

Guru Nanak Auto Enterprises has established itself as a leader in forging capabilities, equipped with upset forging technology, Automatic Direct Drive press with Material Gathering, Mechanical presses – Friction Screw press and drop hammers. Our forging operations range from 450T to 2700T and integrates poke yoke for better process controls. Our adaptive production lines are skilled at customizing processes to meet customer specifications.

Cold Extrusion

Guru Nanak Auto Enterprises is having an exclusive facility of cold extrusion with capacities of 250T and 350T, enabling us to seamlessly transform shafts from larger diameter/shorter length to reduced diameter/ extended length including automatic phosphating/bondrising and stress aligning set up. With this, the product achieves better strength and dimensional accuracy without the need for additional machining process. Our expertise in cold extrusion focuses towards manufacturing high-performance components, particularly for Semi float axle shaft application. This capability reflects our commitment to engineering excellence and sustainable manufacturing practices.

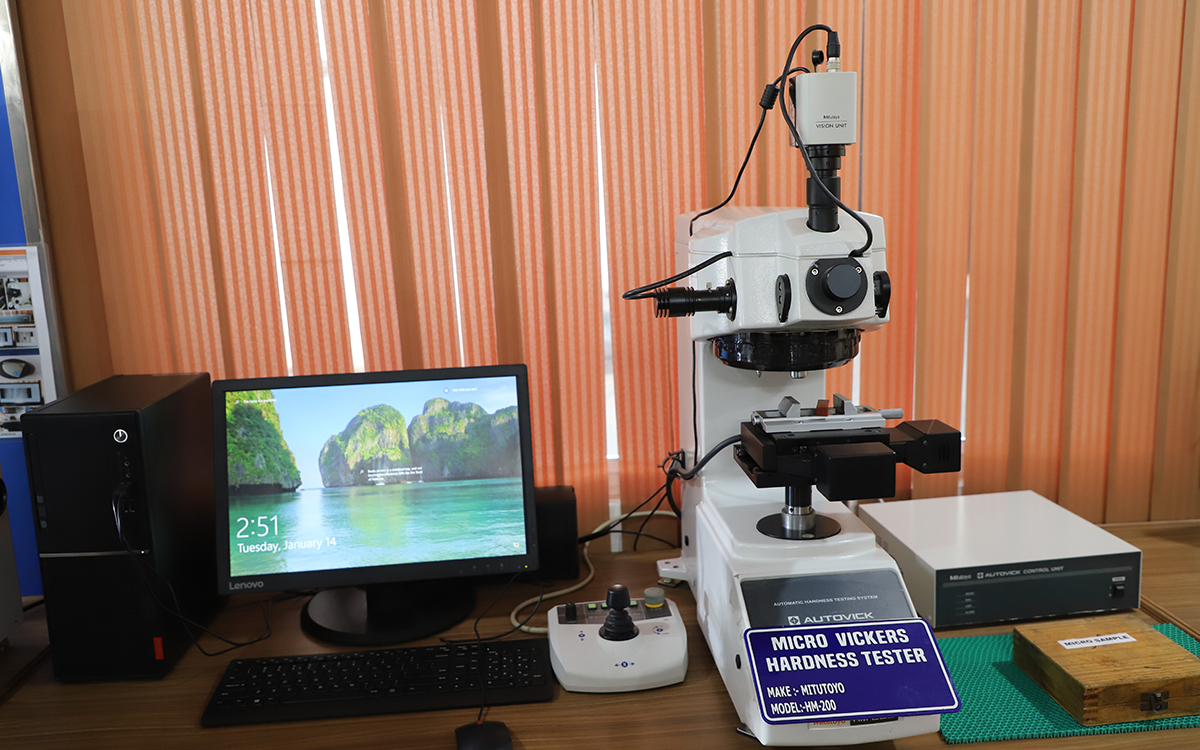

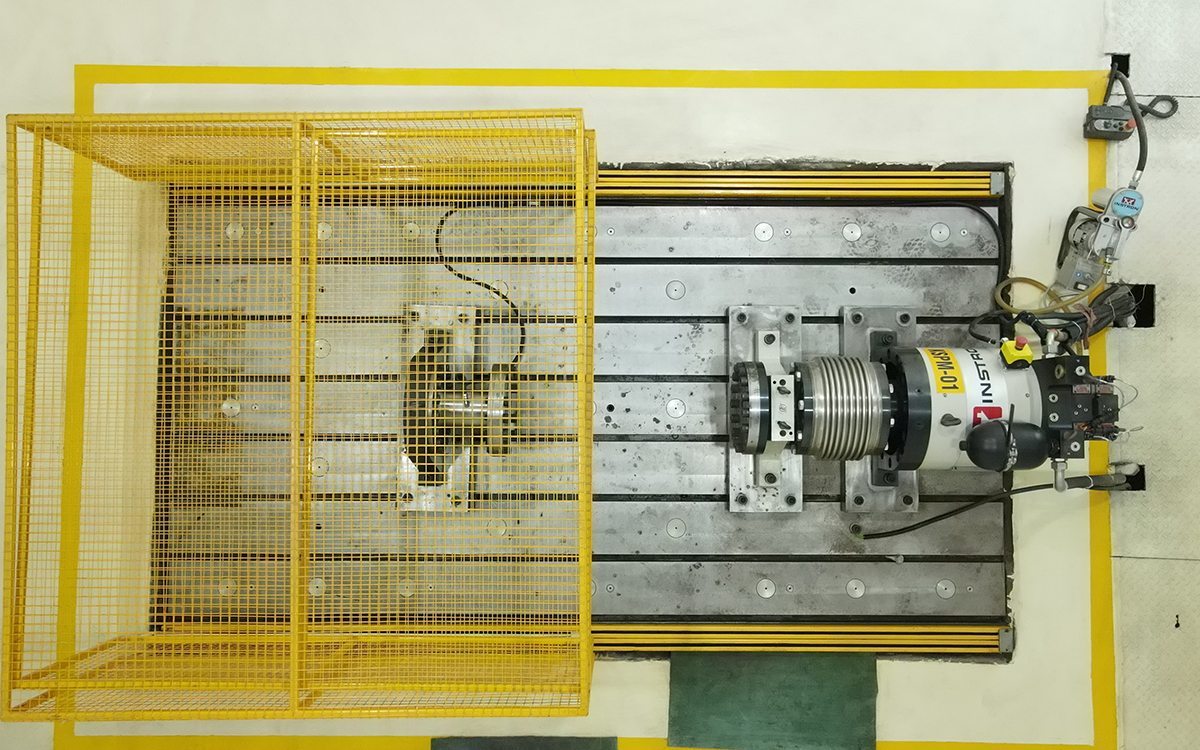

Test Center

Guru Nanak Auto Enterprises features an advanced testing facility equipped with dynamic and static testing equipment essential for validating the part durability under cyclic load condition and also the strength under static conditions. We also have impact testing machine and range of other mechanical and metallurgical testing equipment.

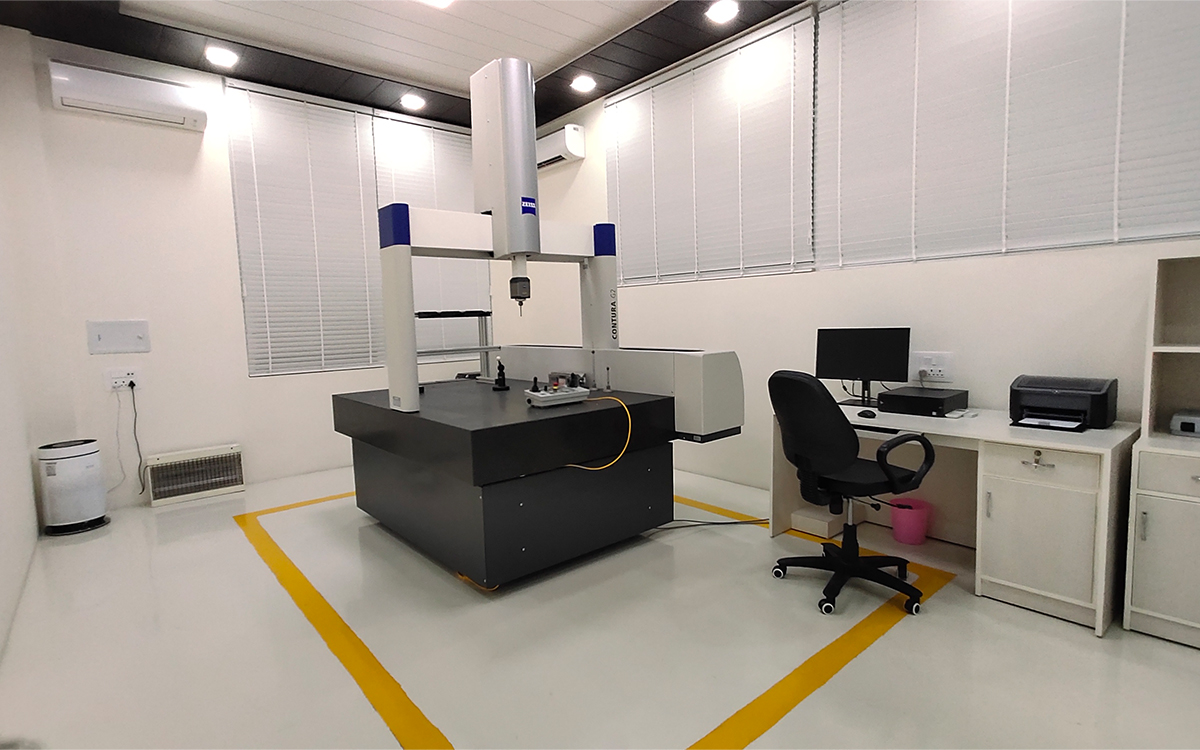

Quality

For GNAE, quality is not just a standard; it’s the commitment to excellence. With a long legacy since 1946, we uphold industry benchmarks in every product. Our state-of-the-art facilities use advanced process controls and digital technologies to establish robust quality systems. Our processes includes the use of automatic straightening machine, Eddy current testers, Magnetic Particle test, Emersion UT for crack testing and auto gauging at the end of line with the support of statistical control and measurement system analysis. Being a Ford Q1 certified supplier and adhering IATF 16949/VDA 6.3 requirements by enhancing our ability to understand and meet customer specific requirements. Our rigorous inspection and testing procedures ensures zero ppm at customer end. We cultivate a culture of quality assurance into every step of our manufacturing process.